gear honing monitoring

Gear Honing Is That Extremely Important Last Step Before Transmission Assembly

Even though the honing process removes only a few microns of material from a gear, it is critical to customer satisfaction. A badly-honed gear can cause transmission squeal. Unfortunately, an un-honed or improperly-honed gear is almost identical in appearance to a correctly-honed gear. The integrity of the honing process must be ensured to prevent suspect gears from ending up in transmissions.

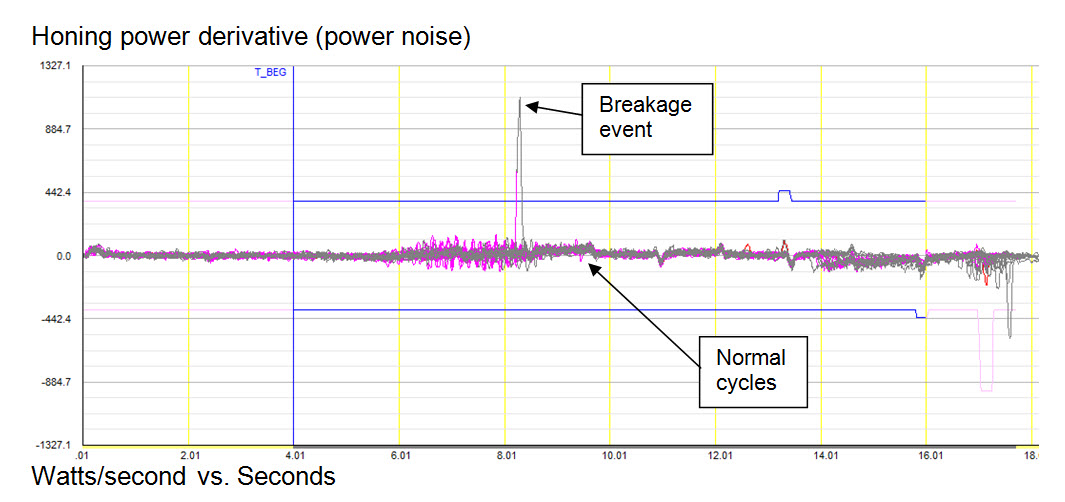

Detect Honing Stone Chipping

WattPilote can detect honing stone chipping even before the stone degradation is severe enough to affect gear quality. It can detect chipping independent of whether the stone has just been dressed or whether it is worn. WattPilote’s proprietary algorithms continuously scan for fast transitions in the power signal that occur at the moment of stone fracture.

Quantify the Variables and Optimize the Honing Process

WattPilote provides a window into the honing process and helps you to answer questions like: How often should the stone be dressed? Was the stone dressed properly? How many gears can I hone before I need to change the stone? Are my speeds and feeds appropriate to produce a quality part? WattPilote can help you improve your honing process and save money.

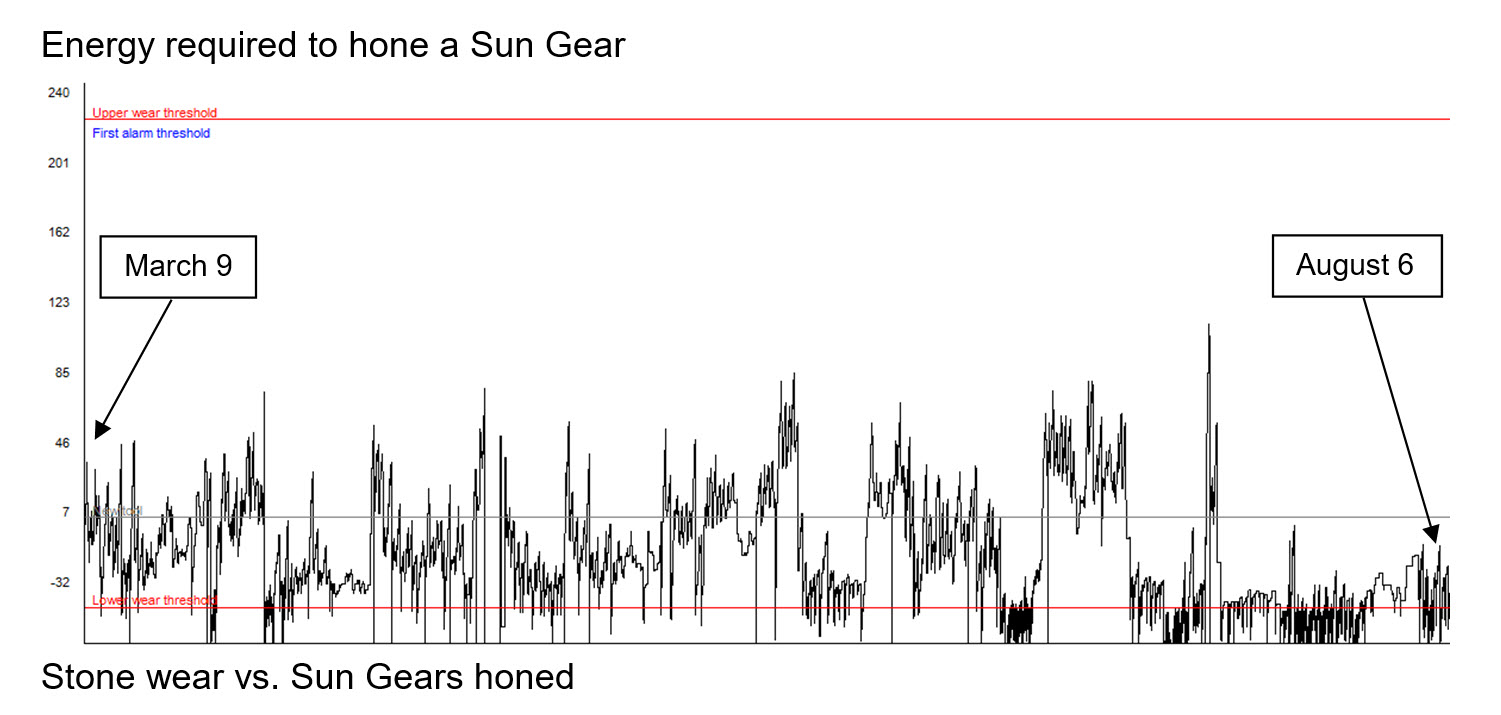

Track and Manage Honing Stone Wear

The amount of energy required to hone a gear is a function of the number of gears honed since the last dressing cycle and the number of dressing cycles previously performed on the stone. This energy is proportional to wear. WattPilote alerts the machine control to excessive stone wear and keeps a record of long-term trends in stone wear.