Carbon Panel Boring

This is a parallax text block. Click the edit button to change this text.

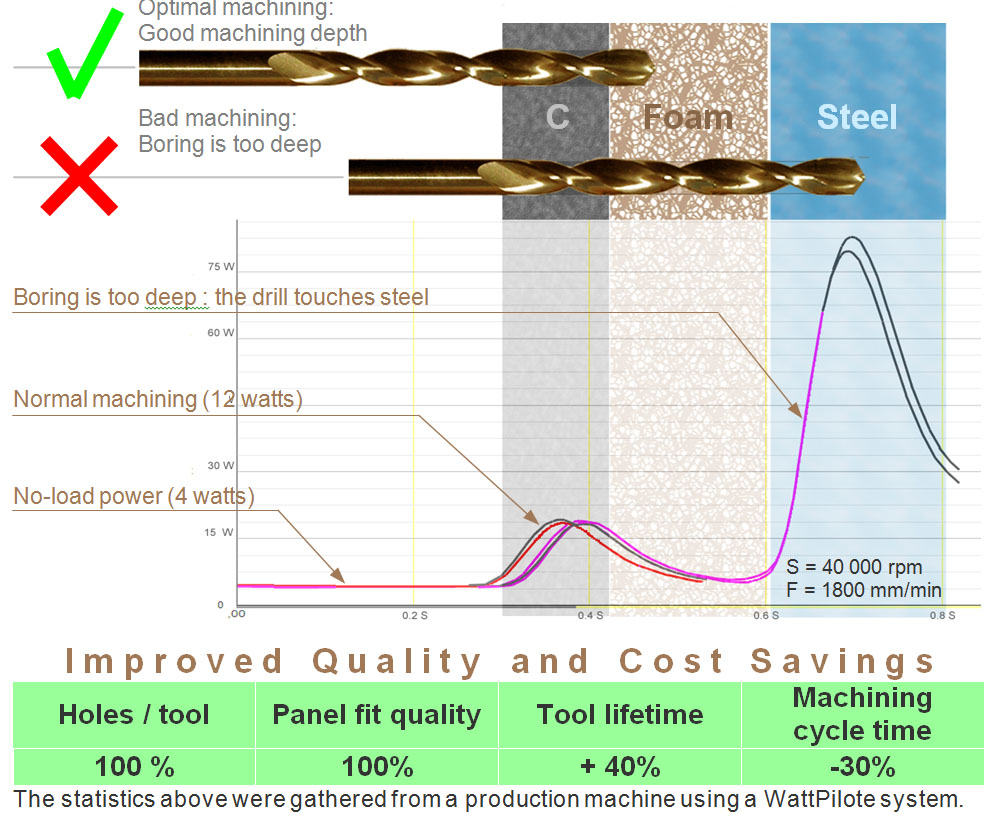

Several thousand 1.5-mm holes are drilled into a 3-mm carbon panel, which is used in the fabrication of jet engine cowlings.

The carbon panels to be machined are mounted on a foam-coated steel plate which acts as a backing liner. WattPilote detects the moment when the carbon panel is completely bored (when the tool starts to bore into the foam) and stops the boring cycle immediately.

- Cycle time optimization As soon as a hole in the carbon panel is completely bored, the unit returns and the next boring cycle starts.

- Quality control WattPilote controls the execution of all boring cycles.

- Tool protection The exact position of the panel is unknown. The WattPilote system prevents penetration depth from becoming too large and avoids the deformation or breakage that can occur if the boring tool touches the steel plate.

- Detection of tool breakage Even if a boring tool should break, carbon panel quality is still assured.